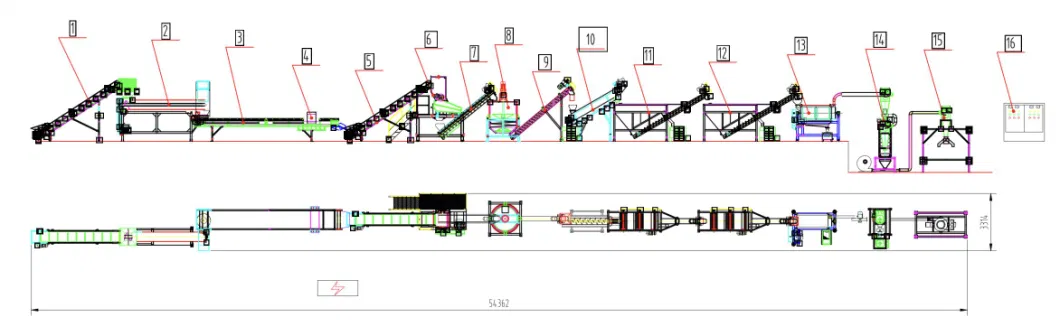

Wasted Used PP HDPE LLDPE Film Scrap PVC Pipe Pet Bottle ABS Car Bump Shredding Crushing Washing Drying Granulating Recycling Pellet Granule Making Machines

Basic Info.

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Condition | New |

| After-sales Service | 1 Year |

| Usage | Plastic Pipe |

| Voltage | 380V /220V |

| Key Words | Piple Making Line |

| Screw | Double Screw |

| Name | PE Extrusion Pipe Making Line Machine |

| Weight | 5-20t |

| Plastic Process | PP/PE/PA/PVC/PE-Rt/Pex/PVDF/ABS |

| Power | 10-295kw |

| Color | Customized |

| Transport Package | Wooden |

| Specification | 28*1.5*10 m |

| Trademark | S&K |

| Origin | Jiangsu |

| Production Capacity | 30 |

Packaging & Delivery

Package Size 1000.00cm * 300.00cm * 400.00cm Package Gross Weight 8000.000kgProduct Description

Plastic PP HDPE LDPE PVC woven bag/agriculture film crushing drying washing plastic recycling machine line

Product description :

1. The main material is PE agriculture film, PE bags, shopping bags, beverage bags, PP woven bags, and some other soft material etc…

2. The main process of the washing line is crushing, washing, drying parts.

3. The capacity of the washing line is from 200kg/h to 1000kg/h.

4. There crusher is to crush the film and woven bags to small pieces with size 70mm to 120mm.

5. Cold water sinking swimming tank can wash the common dirties, like the soil, sand, earth, stone, glass out.

6. High speed friction washer and hot sinking swimming tank can remove the strong dirties, like the grease, oil, glue.

7. With big capacity, double drying system can ensure the final products, PE PP flakes moisture lower than 5%.

8. With squeezing machine, the moisture level of PE PP flakes can be lower than 3%.

9. Final PP PE flakes can be taken directly to the granulating/pelletizing line to make granules/pellets.

Main Technical Parameter :

| Models | Capacity | Total Power | Workers |

| SKL300 | 300kg/h | 95~150KW | 1~2 |

| SKL500 | 500kg/h | 180~250KW | 2~3 |

| SKL1000 | 1000kg/h | 280~380KW | 2~3 |

Machine Parts:Wet crusher : Screw loader : Water washing tank :

1.Dimensions of rotating blade:670mm 1.Effective length: 3500mm 1.Quantity of the washing roller:42.Rotating speed of blade:500r/min 2.Diameter of screw: φ450mm 2.Length of whole machine:7000mm3.Quantity of fixed blade:4 pcs. 3.Speed of diameter: 500-600rpm 3.Width of washer:1300mm

High speed friction washer centrifugal horizontal dewaterer Pipe drying system

1.Rotation method: V-belt 1.Screen Material:Stainless Steel 304 1.Material:304stainless steel 2.Spindle speed: 1630rpm 2.speed of main shaft:1400 Rpm 2.Pipe length: 18 meters 3.Effective length: 2150mm 3.Blade Thickness:10mm 3. Heating power: 36kw4.Mesh diameter: 2.5mm

Order flowing process:

Customer requirements →Scheme designed →confirmed by customers →order fixed →manufacturing →trial running in our factory →confirmed by customers →shipped →engineer available overseas →whole life after sales services

Factory overview:

Pre-sale :

We provide presales service in various forms, for example, making investment budget,manufacturing planning, etc. so that customers make a reasonable plan with less cost.

• Investment budgeting: We provide services of product profit analysis, recommendation of machine and auxiliary equipment and relevant budgeting, human resources allocation and budgeting.

• Plant Planning: We provide the mounting dimension of the equipment base,design of equipment layout, workshop ventilation, water transmission etc.

• Offer information of peripherals

In-sale :• Detailed design of lay-out that is the position of the procession• Technological information of provided products• Schedule about design,manufacturing and installation• Working & Producing progression• Training course for the technician so that the installation is safe and standard

After-sale :• For customers buying our products, we provide them free training so that they can use and maintain the machine independently.

• We will answer customer's question on technology in time. If needed, we will offer on-site guidance and assistance.

• We can provide free technical guidance if customers need new equipment, add or rebuild equipment.

Competitive Advantage:

1. Installation and test running

We will invite customers to check the machine before shipment. And if the customer requests us to guide installment and test running in his factory, we will send our engineer. And the customer should pay for engineer's ticket, visa, room and board, $80 per day for one people as allowance.

2. Quality guarantee

We normally guarantee machine quality for one year to key components of the machines.

S&K Machinery has been dedicated to producing machinery and equipments and carrying out facility construction,pursuing the best quality and producing the best product at the same time. We are committed to reward you with a better quality in return for our interest in and faith toward. We will do our utmost for one more stepping forward,based on our infinite services and trust to customers.

Contact us quickly!!!!!!!!!