Dwc Multilayer Belt Dryer Drying Machine Dehydrator for Vegetables Fruits and Pet Food

Dwc Multilayer Belt Dryer for Vegetables and FruitsWe have a belt dryer project in the United States, and our customers ;

Basic Info.

| Model NO. | DWC |

| Package | Wooden Case |

| Delivery | 30days |

| Certificate | ISO14001 ISO9001 |

| Good Price | Expienced After Sale Service |

| High Efficient, Good Economic | Quick Drying |

| Professional Manufacture | Strong Technical Power |

| Transport Package | Standard Wooden Case |

| Specification | DWT |

| Trademark | Yuzhou |

| Origin | China |

| HS Code | 841939 |

Product Description

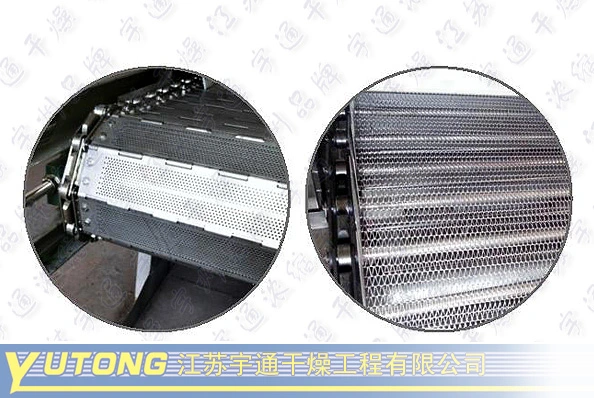

Dwc Multilayer Belt Dryer for Vegetables and FruitsWe have a belt dryer project in the United States, and our customers use it to produce pet food. So far, it has worked very well, bringing a lot of economic value to customers.Jiangsu Yutong Drying Engineering Company is a High-New Technology Enterprise in China. With over 20 years of experience, we are able to provide a wide variety of products, including drying machine, grinding machine, granulator, mixing machine, and more. Features like compact structure, high efficiency, and low energy consumption have resulted in our products being increasingly used in the pharmaceutical, chemical, food, light industry, dyes, mineral products, electronics, ceramics, plastics, agricultural products, pesticides, feed, fertilizers, and other industries. At Yutong, our cooperative relationships with many research institutes and universities enable us to constantly improve product performance and develop new drying machines, mixers and feed machines. As a result of our focus on innovation, we have received many national patents. Application- Chinese medicinal materials/ Herb- seafood- vegetables- fruit- feed granule/ pet food- agricultural products- chemical materials- melon seeds- seaweed- coconut- wood chips- Charcoal Ball- Mulberry Leaf- filter cakesDescriptionDWC multilayer belt dryer is specially designed for drying different shapes of root vegetables and leafy vegetables. This drying machine has three-layer and five-layer structure, each layer can be independently adjusted the drying temperature according to the characteristics of the materials.The working principle of this multilayer conveyor dryer shows as follows: the material is limit controlled by the hopper and is evenly spread on the mesh belt. The materials are driven by the motor to the top layer, then perform uniform motion in the multilayer belt dryer and conduct downward movement layer by layer. Cold air enters from the two axial flow fans, after ballasting via baffle plate, it will flows from bottom to top. There is equipped with a heater under the mesh belt at each layer. The cold air is constantly gradient heated, and then through the material layer. It will conduct mass transfer and heat transfer with the material layer, so that the moisture contained in the material can be rapidly vaporized and evaporated. When the cold air gets to the top layer, it has become saturated moist air, and will be discharged outdoors under the action of exhaust fan. Material Movement and Process DiagramThis conveyor dryer adopts five-layer structure. Materials in the hopper are lifted to the top layer by conveyor belt, and then enter into the drying machine. The materials with the upper belt move to the other end of the multilayer belt dryer, and then slide along the hoop plate down to the next layer. And then the materials along with this layer pass through the conveyor dryer to the other end, and fall to the lowest layer, and so on. The materials along with the lowest belt move to the other end of the drying machine to discharge. Features of Multilayer Belt Dryer1. The hot gas flow passes through the mesh belt and the material layer from bottom to top, thus ensuring uniform heat transfer. This drying machine has high production efficiency and good quality.2. This multilayer conveyor dryer adopts hoisting equipment with uniform feeder, and the thickness of the material layer can be infinitely variable control. Parameters

| Model | DWC-20 | DWC-25 | DWC-32 | DWC-36 | DWC-48 | DWC-60 | DWC-80 |

| Spreading Area (m2) | 20 | 25 | 32 | 36 | 48 | 60 | 80 |

| Steam Pressure (Mpa) | 0.4 to 0.7 | ||||||

| Steam Consumption (Kg/h) | 150 to 300 | 180 to 375 | 240 to 480 | 270 to 540 | 360 to 720 | 450 to 900 | 600 to 1200 |

| Drying Cycle (min) | 20 to 200 | 60 to 600 | 100 to 1000 | ||||

| Evaporation Power (Kg/h) | 100 to 200 | 125 to 250 | 160 to 320 | 180 to 360 | 300 to 480 | 300 to 600 | 400 to 800 |

| Installed Power (kw) | 5.5 | 5.5 | 5.5 | 5.5 | 14.2 | 15.2 | 15.2 |

| Total Weight (Ton.) | 8 | 8 | 8.5 | 10 | 11 | 13 | 15 |

| Outline Dimensions (m) | 8.9 × 2.4 × 3.4 | 9.9 × 2.4 × 3.4 | 11.5 × 2.4 × 3.4 | 12.5 × 2.4 × 3.4 | 13.5 × 2.4 × 3.4 | 14.5 × 2.4 × 3.4 | 15.5 × 2.4 × 3.4 |

CERTIFICATEPackage:wooden case

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer`s requirements.

After-sale service

Provide considerate services to minimize clients` worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

You may also like

Send inquiry

Send now